The Miele PLW 8683 CD ADP Laboratory Glasswasher is a cutting-edge washer-disinfector engineered for the meticulous cleaning and disinfection of laboratory glassware in pharmaceutical, biotechnology, chemical, and academic research settings. Built with Miele’s signature German precision, this model integrates advanced cleaning technology, customizable programming, and eco-conscious design to achieve analytically clean, residue-free results. The PLW 8683 CD ADP features precise process monitoring, integrated liquid dispensing, and a robust drying system, making it an ideal solution for laboratories demanding high throughput and compliance. Its versatile design ensures seamless integration into modern workflows, delivering reliability and efficiency.

Key Features

-

Exceptional Cleaning Performance: Employs a variable-speed circulation pump to optimize water pressure, delivering powerful cleaning for tough residues and gentle soaking for thorough coverage. Enhanced spray arm design and a multi-stage filtration system ensure pristine results for laboratory glassware, from pipettes to flasks.

-

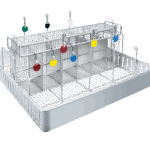

Flexible High-Capacity Chamber: Accommodates up to 128 laboratory bottles, 98 pipettes, or 196 vials per cycle, with stacking options for mixed loads (e.g., 64 bottles with 196 vials). The EasyLoad system and modular racks simplify loading, supporting diverse glassware sizes and shapes for maximum efficiency.

-

Advanced Drying Technology: Features Miele’s DryPlus system with high-efficiency hot air drying and a HEPA H14 filter, ensuring particle-free, spotless drying of glassware, including narrow-necked items, for immediate use without manual intervention.

-

Comprehensive Process Validation: Monitors wash pressure, spray arm performance, and optional conductivity levels to ensure consistent outcomes. Integrated dosing pumps with flow meters provide accurate chemical delivery, while WiFi connectivity supports detailed cycle documentation, aligning with Good Laboratory Practice (GLP) and Good Manufacturing Practice (GMP) requirements.

-

Customizable Programming: Equipped with a vibrant M Touch Flex color touchscreen, offering intuitive access to pre-set programs and 20 preset cycles and 10 freely programmable programme slots. Adjustable parameters, such as pump speed and wash phases, cater to specialized needs, including delicate glassware or heavy soiling.

-

Durable Hygienic Construction: Features a stainless steel chamber with laser-welded seams and external heating elements to maintain a crevice-free, hygienic environment.

-

Eco-Friendly Operation: Reduces resource consumption through a variable-speed pump. Demineralized water (AD) integration ensures residue-free rinsing, supporting sustainable laboratory practices.

-

User-Friendly and Service-Optimized: Offers a flush-fit touchscreen for easy operation, and a maintenance-friendly design for minimal downtime, backed by SiC’s own Miele trained Engineers.

-

Robust Safety Measures: Includes real-time monitoring of spray arms and pressure, automatic door locks, and conductivity checks to prevent residue carryover, ensuring operator safety and reliable reprocessing.

Applications

-

Pharmaceutical Research: Cleaning of glassware used in drug development and quality assurance, ensuring no cross-contamination.

-

Biotechnology Labs: Reprocessing of pipettes, vials, and flasks for cell culture and molecular experiments, maintaining sterility.

-

Chemical Analysis: Removal of oil, grease, and chemical residues from analytical glassware for precise results.

-

Academic Institutions: Cleaning of laboratory utensils for teaching and research, supporting experimental accuracy.

-

Food and Beverage Testing: Reprocessing of glassware for microbiological and quality control, with tailored programs for specific residues.